Solsylva 25inch X 25inch CNC router.

The Big CNC machine, I built it because I needed something more permanent, accurate, robust… Together with my friend from work we embarked on the mission of building two !! identical CNC router’s. Whenever we can, we get together on Saturdays, for over a period of 7 months. All wood and most material used came from his storage of leftover’s from old projects.

The plan drawn with sketchup.

Pipe cut,drilled and fitted on the X axis.

I finally agree you can’t have too much clamps..!

It’s moving..!! Y axis, one axis down two more to go.

Next we moved the two machine to my workshop, I glued the remaining pieces of the Z axis and fit the wood which holds the router in between two pipes.

The plan requires sitting the support bearing in a recess, used old kitchen cutting board, drilled with the drill press and cut to marked out sizes using the band saw.

with the Z axis carriage installed, I had free (manual) movement on all 3 axis …!! These machine is turning out to be more rigid than expected.!! There is no play on all axis not even 1 mm…

The machine are so identical I was confused on which to to take. Finally one of the machine went back to my friend to finish the build, I took mine apart and painted it with 2 coats metallic grey and 2 of varnish to seal it.

Finally after what looks forever, the timing belts and pulleys arrived. The delivery was delayed I guess because I had to pay import duty on them. We could not find a supplier in Europe with the right specs. Order from SDP/SI

My friend suggested a brilliant Idea of making the tensioner free and adjustable, he cut out the plate and tapped it with M8 to hold them in place.

With all axis complete I tested the CNC using the motor driver from the small CNC..

I got movement on all axis. (very very slow.) this machine needs a driver ten times bigger and a motor 5 times more powerful. The build plan suggest using a 269 oz.in stepper motor.

All required now, was the electronics (3 Stepper motor, 3 Stepper drivers, a breakeout board, power supply for the motors and the board).

Price ranging from ($300 to $700) for a decent kit.

This is turning to be the most expensive/scary part of the build, It turns out the only way out was to sell the small CNC. I put it up online for sale and it was picked up by a lucky guy. I had the electronics ordered and sent to a US address, I picked it up while in the US, saved us shipping fee. As an over kill we went for the 425 oz.in 3 axis CNC electronics kit from Automation Tech.

You never can tell if there is a need to build an even bigger one… Kind of glad on the choice of electronics, its feel tough, and unbreakable!!.

No time for fancy electronics box, I threw all the drivers on a piece of chipboard, screw them and lay the wires in the pvc “thing” for covering exposed wires(not sure of the correct name). Did some test run, when OK, I mounted the board directly to the wall in my workshop.

And just like magic..!!! the machine was alive!! with beautiful sounds from the motors. Untill my wife came to drag me out of the workshop, I could not stop moving the whole thing in all direction!!

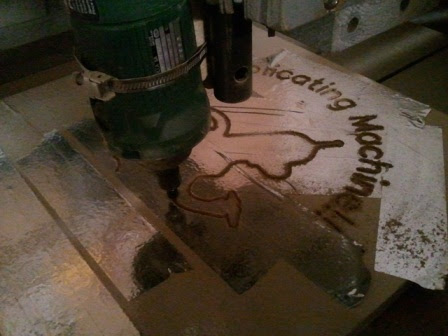

I loaded up some old Gcode from the previous CNC machine, It cut and engraved the three letters flawlessly and 10 times faster.

After sevrall cut, I noticed wood dust building on the drivers, time to make a box to house them. I used the machine to make the engraving on the cover/door for controller.

I covered the whole door with tape, it keeps the bit from getting hot and prevents burnout. Painted the engraving using water based acrylic paint. Pilling of the tape once dry reveal it all. As you might have noticed I named the machine “Bender” (Futurama).

This build would not have been easy without support from my friend, my wife and my workshop assistant (My 15 mnth old son). He jumps at the opportunity to run away with tools!!

And the build would not have been possible with out GOD who is my strength and guide . ( Jump on God’s train, HE makes the impossible possible)

….hmmm have to engrave that..why not (lol)?